IL-47: Testing of Y-TZP samples according to ISO 13356

Yttria-stabilized tetragonal zirconia polycrystal (3Y-TZP) is commonly used for mechanically highly stressed components due to its exceptional hardness and toughness. This includes applications such as ceramic joint heads and dental implants — the latter also benefit from the white color of 3Y-TZP, which offers an aesthetic advantage over grey titanium implants.

The ISO 13356 standard is a comprehensive set of rules for testing 3Y TZP raw materials and test specimens in a medical technology context. It enables the evaluation of material properties and manufacturing processes with regard to safety, functionality and durability - key aspects for the reliability of medical implants and patient safety.

Since the beginning of 2025, the RMS Foundation has been offering the complete characterization of 3Y-TZP samples in accordance with ISO 13356 as an accredited service. All tests are certified according to ISO/IEC 17025. Below you will find an overview of the analyses offered with the respective chapter numbers of the standard:

Bulk density (4.2)

The density is determined either geometrically or using the immersion method in accordance with ISO 18754. Test specimens with a defined geometry - such as those for the 4-point bending test - are ideal for this non-destructive measurement.

Chemical composition (4.3)

The contents of ZrO₂, HfO₂, Y₂O₃ and Al₂O₃ are determined using X-ray fluorescence (XRF) in the powdered starting material. Other potentially present minor and trace elements are detected by "element screening". The detection limits are different for all elements, typically in the range of 0.001 to 0.5 percent by weight. Heavy elements have lower detection limits than light elements.

Microstructure (4.4)

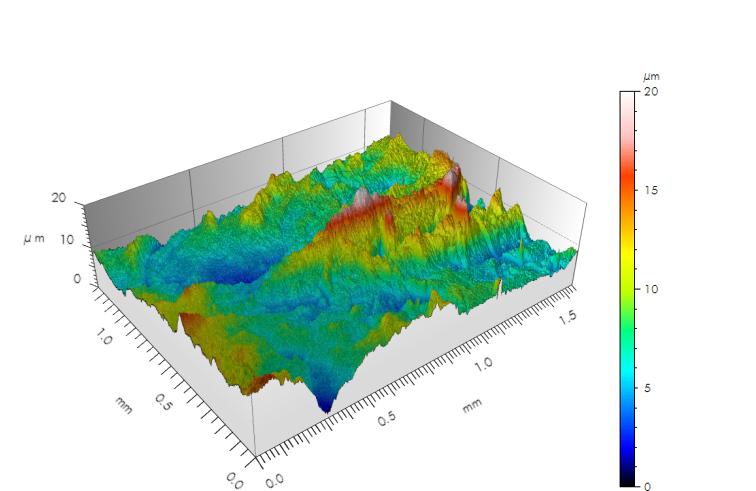

Grain size: The average grain size is determined in accordance with ISO 13383-1 using a line-cut method. For this purpose, the sample is polished, thermally etched and then analyzed under a scanning electron microscope (SEM) (Fig. 1).

Figure 1: Grain structure of a polished and thermally etched 3Y-TZP sample. The thermal etching makes the grain boundaries clearly visible as lines, which facilitates the determination of the grain sizes. The dark pits are pores in the analyzed surface.

Monoclinic phase fraction (amount of monoclinic phase): The amount of monoclinic phase is measured using X-ray diffraction (XRD) on the surface of suitable test specimens (specimen diameter 36 mm, thickness 2.0 mm) (Fig. 2). Alternatively, fragments from the 4-point bending test are also suitable.

Figure 2: Determination of the monoclinic phase fraction (green) of a 3Y-TZP sample using XRD after accelerated ageing. Monoclinic zirconium oxide is formed by a modification of the tetragonal 3Y-TZP crystal structure. The transformation of the tetragonal into the monoclinic phase is favored by moisture and heat. Compared to 3Y-TZP, the monoclinic phase has a much lower mechanical strength, which is why the initial proportion before and after accelerated ageing must not exceed a specified limit value.

Four-point bending strength (4.6)

The bending strength is determined using a 4-point bending test in accordance with ISO 14704 (Fig. 3). For this purpose, samples with a standardized geometry (45 × 4.0 × 3.0 mm) are loaded until they break. At least 30 samples must be tested to calculate the Weibull modulus.

Note: Only methods 2a (4-point bending test) and 2b (calculation of the Weibull modulus) according to ISO 13356 are offered. The alternative methods 1a (biaxial bending) and 1b are currently not available.

Figure 3: Test setup of the 4-point bending test to determine the flexural strength of ceramic specimens. By using a 4-point bending test (i.e. two support rollers at the top and bottom), a constant bending moment is applied between the two inner rollers. The rollers have some room to move freely while the load is applied from above. Below left is a detailed view showing the sample (white) and its guidance within the device.

Weibull modulus (4.7)

The Weibull modulus, a measure of the reliability and dispersion of strength, is calculated from the results of at least 30 bending tests.

Young's modulus (4.8)

The Young's modulus is determined in accordance with EN 843-2 on at least three test specimens with a defined geometry (45 × 4.0 × 1.5 mm).

Hardness (4.9)

The Vickers hardness is measured in accordance with ISO 14705. The same samples that are used to determine grain size are suitable for this purpose.

Cyclic fatigue test (4.10)

The samples are tested in 37 °C warm NaCl solution at a minimum load of 320 MPa and a frequency of 20 Hz over one million load cycles. The method is carried out according to ISO 22214, whereby at least 5 test specimens are required.

Radioactivity (4.11)

The radioactivity is determined by a Swiss partner institute accredited to ISO/IEC 17025 as a subcontractor.

Accelerated aging (4.12)

Accelerated aging is carried out at 134 °C in a saturated water vapor atmosphere for 5 hours. The monoclinic phase fraction (XRD) and flexural strength (4-point test) are then determined on the aged samples.

With this comprehensive offer, the RMS Foundation provides a complete and accredited characterization of your 3Y-TZP implant components according to ISO 13356. For further information and pricing, please contact Stefan Röthlisberger. The following experts will be happy to answer any questions you may have about the individual methods:

- Dr. Anselm Loges (Chemical Analysis)

- Dr. Moritz Liesegang (Microstructure)

- Stefan Röthlisberger (Mechanical testing)

- Dr. Nicola Döbelin (monoclinic phase fraction)

We look forward to hearing from you!

Contact for the characterization of your 3Y-TZP implant components according to ISO 13356:![]()

Stefan Röthlisberger

Phone +41 32 644 20 27