IL-48: Welcome to our new laboratory - now with cutting-edge XPS technology!

In May 2025, we moved into our brand-new laboratory building – and at the same time took our analytical capabilities to the next level with the PHI Genesis from Physical Electronics / ULVAC-PHI, the latest instrument for chemical surface analysis.

With X-ray Photoelectron Spectroscopy (XPS), the top 5–10 nanometers of a sample can be analysed with outstanding precision. Almost all elements – except hydrogen and helium – can be detected, including their chemical binding states. Even the smallest traces of residues (as low as 0.1 at% or about 1 ng/cm²) can be reliably identified.

![]()

Delivery of the new PHI Genesis XPS system to the new laboratory building

Where does XPS make the difference?

- Cleanliness analyses: Detection of production and cleaning residues, such as zinc from lubricants or phosphates from cleaning agents.

- Stain and residue analyses: Precise determination of composition and comparison with adjacent material.

- Surface modifications: Investigation and verification of targeted chemical functionalizations.

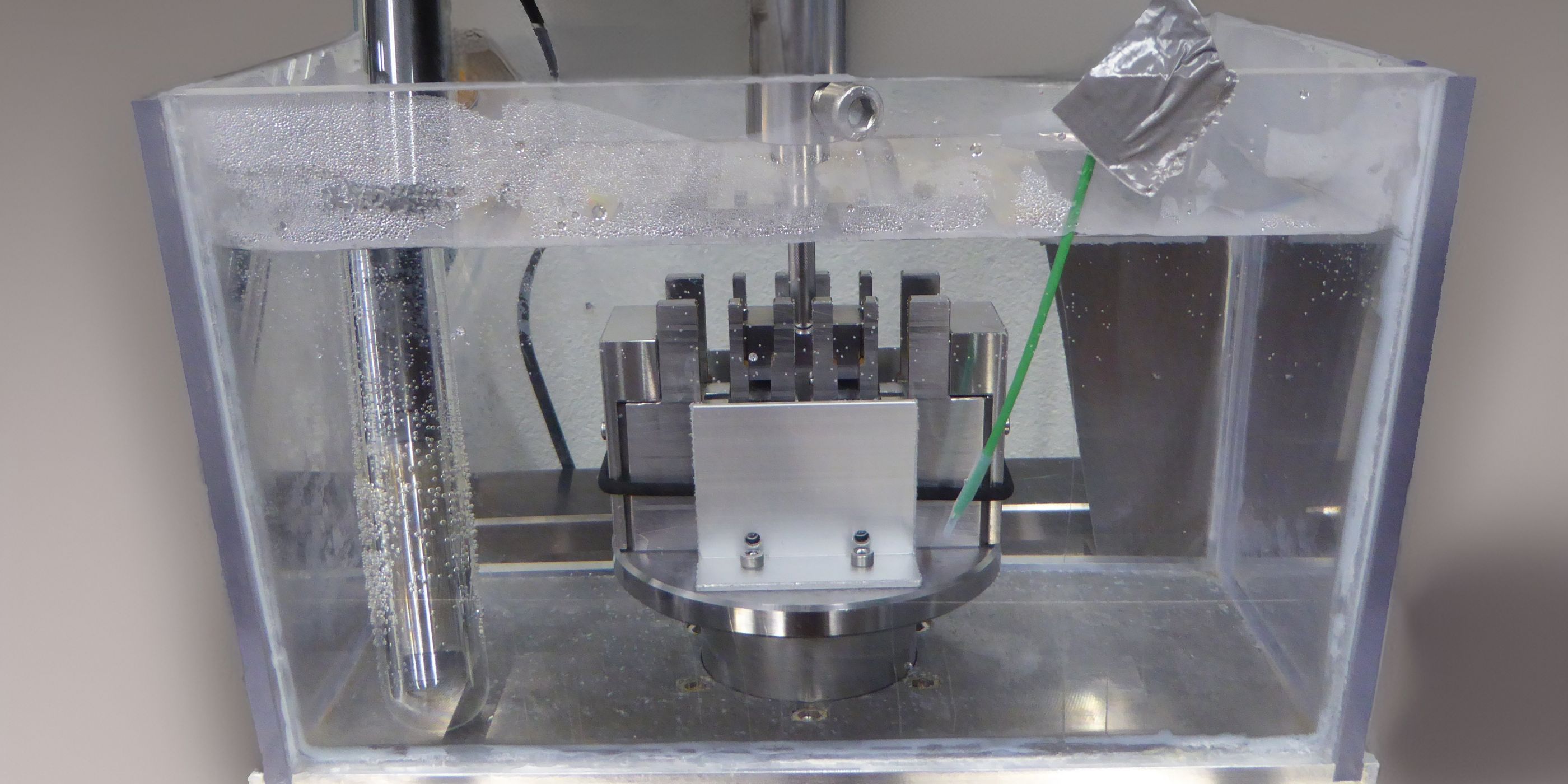

![]()

Inside view of the new PHI Genesis at RMS Foundation

What's new?

- Microscale resolution: The new system enables targeted analysis of structures as small as 5 µm.

- SXI mode: Thanks to secondary electron imaging, even the smallest areas of interest can be selected and analysed with pinpoint accuracy – almost like with a scanning electron microscope.

![]()

SXI image for locating analysis spots on the sample

What remains unchanged?

We continue to be the only laboratory in Switzerland accredited to perform XPS analyses in accordance with ISO/IEC 17025, offering a comprehensive range of services :

- Cleanliness analysis to detect process aids and cleaning agents on the surface.

- Analysis of stains and residues to identify possible sources or causes.

- Verification of chemical surface modifications and functionalisation processes.

- Special analyses, such as:

- Angle-resolved measurements: By tilting the sample, the information depth can be reduced further, allowing detailed investigation of elemental depth distribution at the surface.

- Depth profiling: Using sputtering, the sample is gradually ablated to measure the chemical composition at various depths.

- Imaging XPS: Chemical mapping of the surface with lateral resolution.

Application example

![]()

Application example from medical technology: XPS spectrum of a delaminated layer from a green-anodised titanium sample. An additional fluorine peak is observed. Based on the binding energy, it can be concluded that the fluorine originates from a fluoride, not from polyfluorinated alkyl substances (PFAS). The presence of titanium fluoride at the interface ultimately led to adhesive failure of the coating. The fluoride can be traced back to hydrofluoric acid (HF) etching used in a previous manufacturing step.

Our promise: With advanced XPS analytics, you will receive even more precise answers to your questions - from process residue to targeted surface functionalization.

We look forward to supporting you with our expertise.

Contact us - we will be happy to advise you!

|

|

| Dr. Roman Heuberger Head of Materials Testing and Consulting Phone +41 32 644 20 22 |

Dr. Moritz Liesegang Team Leader Material Structure Phone +41 32 644 20 03 |